At its heart, pressure-treated timber is just standard wood that's been given a serious upgrade to fight off rot, mould, and pesky insects. This is done through a chemical treatment process that dramatically extends its life, which is absolutely essential for any outdoor project facing the famously damp British weather. It’s become the go-to material for everything from garden decking and fence posts to structural joists.

Understanding Pressure Treated Timber

Think of it like this: trying to protect a normal piece of wood outdoors by just painting it is a bit like trying to waterproof a sponge by painting its surface. Sooner or later, moisture will find a way in and start causing trouble from the inside. A simple coat of paint or stain only protects the outside, but it can’t stop damp from creeping into tiny cracks or freshly cut ends.

Pressure treatment offers a far more thorough solution. Instead of just a surface coating, it forces protective chemicals right into the very cells of the wood. This changes the timber on a structural level, fortifying it against the natural elements that would otherwise cause it to decay.

The Treatment Process Explained

The magic happens inside a massive, sealed metal cylinder called a retort. It’s a highly controlled process that ensures the wood is protected through and through.

Here’s a breakdown of how it works:

-

Initial Vacuum: First, the timber is loaded into the chamber. A powerful vacuum then sucks most of the air out of the wood’s internal cells. This creates a sort of empty space, priming the wood to soak up the preservative liquid like a straw.

-

Flooding the Chamber: Next, the chamber is flooded with a water-based preservative. Modern treatments are typically copper-based, which is what gives the freshly treated wood that distinctive faint green or sometimes brown tint.

-

Applying High Pressure: Finally, intense hydraulic pressure is applied. This is the crucial step that forces the preservative deep into the wood’s structure, ensuring it penetrates far beyond the surface for long-lasting protection.

This industrial-scale process guarantees that the entire piece of timber, not just the outer layer, is shielded from rot and pests. For any project where you need both strength and durability, like the joists for a deck, you’ll want a reliably treated product. Our range of C24 treated carcassing timber is a perfect example of timber treated for performance.

The real secret to pressure treatment is deep penetration. It’s not a paint job; it’s an internal shield that makes the wood an unwelcome home for the fungi and insects that cause decay.

Ultimately, this whole process transforms a vulnerable, organic material into a tough, dependable building component. It’s what makes pressure-treated timber the smart choice for almost any construction that needs to stand up to the elements, ensuring your garden structures, fences, and decks stay solid for many years.

Why Choose Treated Timber for Outdoor Projects

When you’re planning any kind of outdoor project in the UK, whether it’s a sprawling new deck or a simple garden fence, your choice of material is everything. Let’s be honest, our weather isn’t kind to wood. The constant damp, driving rain, and unpredictable temperatures can make short work of unprotected timber.

This is exactly where pressure treated timber proves its worth, making it the go-to choice for almost any job you can think of outside.

Its biggest selling point is sheer durability. The treatment process forces preservatives deep into the wood's core, creating an impressive defence against the two things that destroy timber: fungal rot and wood-boring insects. This built-in protection means your deck, pergola, or fence will stay strong and safe for years, lasting far longer than any untreated wood ever could.

Long-Term Value and Versatility

It’s true that pressure treated timber might cost a little more upfront compared to untreated planks. However, think of it as a long-term investment. By fighting off decay from day one, you’re saving yourself a world of hassle and expense in future repairs and replacements. It's the classic "build it once, build it right" philosophy.

The sheer versatility of treated timber is another reason it’s so popular with both DIYers and professionals. It’s a real workhorse material suitable for a huge range of projects:

- Structural Supports: Perfect for the heavy-lifting parts of a build, like deck joists and fence posts that need to be strong and often sit in direct contact with the ground.

- Surface Applications: An obvious choice for decking boards, fence panels, and cladding that face the full force of the weather year-round.

- Garden Features: Great for building everything from raised vegetable beds and retaining walls to custom garden furniture and planters.

A More Sustainable Choice

Opting for a material that lasts is also a smart move for the environment. When your timber structures don't need replacing every few years, you reduce the overall demand for newly harvested wood. This helps support responsible forestry and ensures our woodlands remain a healthy, renewable resource for generations to come.

Pressure treated timber isn't just about building something that lasts; it's about making a smarter, more cost-effective, and environmentally conscious decision from the outset.

If you’re looking for a bit of inspiration, checking out creative DIY backyard playground ideas often shows just how essential a tough, weather-ready material like treated timber is. And remember, the protection doesn’t stop after installation. To keep your project looking fantastic and boost its weather resistance even further, you can find a whole range of suitable wood treatments designed for aftercare.

Choosing the Right Timber Use Class

Let's get one thing straight: not all pressure treated timber is created equal. Picking the right grade for your project isn't just about what looks good; it's absolutely critical for the safety and lifespan of whatever you're building. Think of it like this: you wouldn't use interior emulsion to paint the outside of your house, would you? The same logic applies here. You can't expect timber treated for a dry, indoor space to survive a wet British winter in the garden.

This is exactly why we have the Use Class system, which is set out in the British Standard BS 8417. It’s a simple, no-nonsense classification that tells you precisely what environment a piece of treated wood is designed for. Getting to grips with these classes is the secret to preventing early rot and structural failure, saving you a world of hassle and money down the line.

Breaking Down the Use Classes

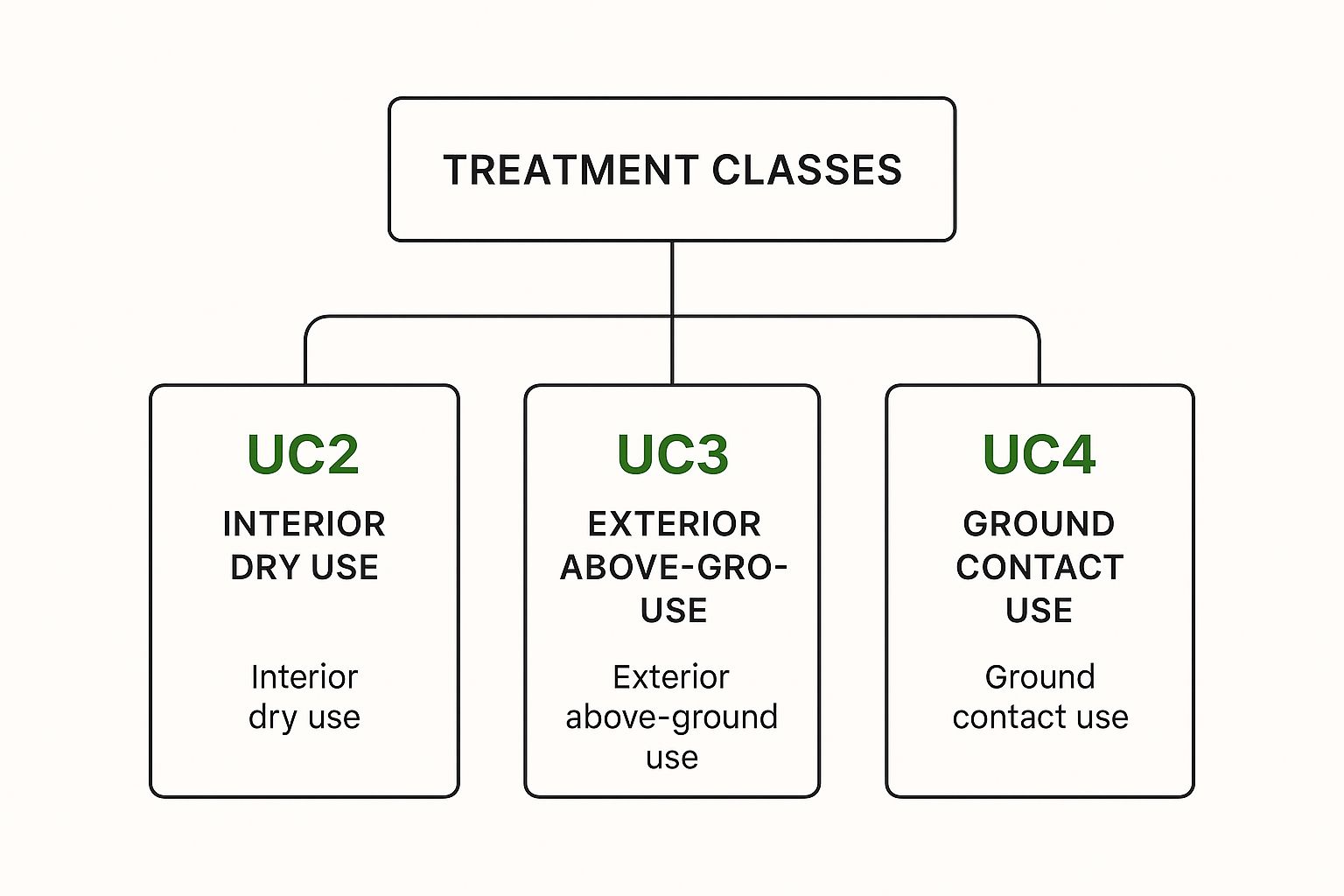

The system is organised by numbers – the higher the number, the more intense the preservative treatment and the better it can fight off decay. For most of us doing DIY or construction jobs, the classes you'll bump into most often are Use Classes 2, 3, and 4.

-

Use Class 2 (UC2): This is your indoor timber. It’s designed for dry environments where there's just a slight risk of dampness, like condensation. Think of internal framing, floor joists in a room with good airflow, or the trusses up in your loft. It's got some protection, but it’s definitely not ready for the great outdoors.

-

Use Class 3 (UC3): Now we're outside. This is the go-to class for any timber that's going to be above ground but exposed to the weather. It's treated to handle the rain and sun. This is what you need for decking boards, fence panels, garden furniture, and exterior cladding.

-

Use Class 4 (UC4): This is the heavy-duty stuff. UC4 is reserved for timber that will be in direct contact with the ground or fresh water. The preservative treatment is much more potent to stop it from rotting in constantly wet conditions. For things like fence posts, the support posts for your deck, and gravel boards, anything less than UC4 is a mistake.

This simple diagram helps to show the difference between the main treatment classes you'll come across for most building projects.

The crucial thing to remember is that the risk of rot shoots up the moment timber goes outside, and it becomes even more serious when that wood is touching the ground.

A Guide to Timber Use Classes (BS 8417)

To make sure you’re buying the right stuff, here’s a quick-reference table. It breaks down the UK Use Classes for treated timber, detailing the level of risk and common applications for each to help you choose the correct wood for your project.

| Use Class | Environment Type | Typical Applications |

|---|---|---|

| UC2 | Interior, dry, risk of condensation | Roof timbers, internal joists, sole plates |

| UC3 | Exterior, above ground | Decking boards, fence panels, cladding |

| UC4 | Exterior, in ground or fresh water contact | Fence posts, deck posts, gravel boards |

Always check the label or ask your supplier if you're unsure. By getting familiar with this system, you can choose your timber with confidence, knowing that your project is built to last from the ground up.

How to Safely Work With and Install Treated Timber

Working with pressure-treated timber isn't complicated, but the chemical preservatives do mean you need to take a sensible approach. A few key precautions during handling and installation will protect both you and the long-term integrity of your project.

First things first: personal safety. While the treatment chemicals are locked into the wood's fibres, cutting or drilling creates fine dust. You don't want to be breathing that in or getting it in your eyes. Always wear gloves, proper eye protection, and a decent dust mask whenever you’re sawing or sanding.

It’s also a good idea to work outside if you can, or at least in a well-ventilated space, to let any dust scatter. For a more detailed look at best practices on a building site, this practical guide to safe work procedures is a great resource.

Don't Skimp on the Fixings

One of the most common—and costly—mistakes I see is people using the wrong screws or nails with treated timber. The copper-based preservatives are brilliant at stopping rot, but they’re also highly corrosive to plain old steel. Standard fixings will rust and fail surprisingly fast, leaving you with a weak and dangerous structure.

To prevent this, you must use corrosion-resistant fixings. No exceptions.

- Hot-Dipped Galvanised: These are your go-to. They're coated in a thick layer of protective zinc that stands up well to the chemicals in the wood.

- Stainless Steel: This is the best-in-class option. It offers the ultimate protection against corrosion, making it a smart choice for coastal areas with salty air or for any project where you want maximum durability.

Think of the right fixings as an essential investment in the safety and stability of whatever you're building.

Always Treat Your Cut Ends

The protection from pressure treatment is fantastic, but it does have a weak spot: any new cut you make. When you slice through a piece of treated timber, you expose the untreated core. That fresh wood is like an open door for moisture and rot, completely bypassing the protective chemical barrier.

Failing to treat cut ends is like building a waterproof boat but leaving a small hole in the hull. It might not seem like a big deal at first, but eventually, water will get in and cause serious damage.

This is why sealing any freshly exposed timber is absolutely critical. Grab a brush and apply a generous coat of an end-grain preservative to any surface you've cut, drilled, or notched. This simple step re-seals the wood, ensuring the entire piece is protected from the elements. It's a small job that can add years to the life of your deck, fence, or garden structure.

Maintaining Your Timber for a Longer Lifespan

It’s easy to think that "pressure treated" means you can just install your timber and forget about it. While the treatment does an amazing job of fighting off rot and insects, it won't stop the sun and rain from doing their thing.

To keep your project looking sharp and get the most out of your investment, a little bit of annual TLC is all it takes. This simple aftercare routine will make sure your decking, fencing, or garden structure holds up for years, both in strength and looks.

Your Annual Maintenance Checklist

Anything left outside is going to get dirty. Over the year, your timber will pick up a layer of dirt, pollen, and maybe even a bit of green algae, particularly in those damp, shady corners. A good clean once a year, usually in the spring, gets rid of all that grime and preps the wood for a fresh coat of protection.

For most surfaces, a stiff brush and a bucket of soapy water will do the trick. If you're dealing with a really grubby deck, a pressure washer on a low setting can make quick work of it. Just be careful not to get too aggressive, as high pressure can easily gouge the wood and damage the fibres.

Remember, maintaining pressure treated timber isn't about preventing rot—the treatment has that covered. It's about protecting the wood's surface from the cosmetic effects of weathering, like turning grey or developing small cracks.

Once the timber is sparkling clean and has had a chance to dry out completely, it's time to protect it. Applying a good quality finish every couple of years is the secret to preserving the wood’s colour and condition.

Applying Sealants and Stains for Protection

A protective finish is your timber’s first line of defence against the two biggest culprits of weathering: moisture and UV light. The sun’s rays will slowly bleach the wood to a silvery grey, and the constant cycle of getting wet and drying out can cause small surface cracks to appear.

You’ve got two main options here:

- Water-Repellent Sealants: These are usually clear coats that form a barrier, stopping water from soaking into the grain. This really helps to minimise the swelling and shrinking that leads to splits and warping.

- UV-Protective Stains: These products have pigments that act like sunblock for your timber, helping it hold onto its natural colour for much longer. They also do a great job of sealing out moisture.

If you’re after an all-in-one product, you could look at something like a multi-purpose wood treatment which offers protection against everything. Whichever path you choose, this simple step will pay you back tenfold by extending the life and look of your outdoor project.

Sourcing Timber in the UK Market

When you're pricing up a project using pressure treated timber, you'll find that cost and availability are tied to a whole web of local and global influences. The UK market is an interesting mix of home-grown wood and international supply chains, and getting your head around it can make you a much smarter buyer.

A massive factor is just how much wood the UK brings in from overseas. To keep up with the huge demand from construction and manufacturing, the UK has to import roughly 80-85% of its timber. This heavy reliance means that global events, fluctuations in shipping costs, or new trade agreements can have a direct knock-on effect on the price you see at your local builders' merchant. You can dig deeper into the numbers on UK wood production and trade with this report from Forest Research.

This imported timber, which mostly comes from Scandinavia and other European countries, has to pass strict biosecurity and quality checks. It's often treated before it even gets here or once it lands to make sure it's up to the job for our specific climate and building regulations.

The Role of Domestic Forestry

While imports are the bigger piece of the pie, we do have a solid domestic forestry industry right here in the UK. Scotland, in particular, is a key player, producing a lot of the softwoods like spruce and pine that are ideal for pressure treatment because they absorb the preservatives so well.

Having a supply of home-grown timber helps to steady the market and gives us a more local, and often more sustainable, choice. The simple truth, however, is that domestic forests can't produce nearly enough to meet the country's needs on their own. This is why that balance between imported and local wood is so crucial.

Understanding this market dynamic helps explain price fluctuations. A disruption in a Baltic port or a surge in UK housing starts can ripple through the supply chain, affecting the cost of the sawn timber needed for your garden fence or decking.

At the end of the day, finding the right wood is all about navigating this landscape. Whether you need specific dimensions or a particular treatment grade, looking through a good inventory of quality sawn timber from a supplier you trust is the best way to get your project off to a flying start.

Your Questions Answered

Even when you've got the basics down, working with pressure treated timber can throw a few curveballs. Let's tackle some of the most common questions that pop up, so you can move forward with your project feeling confident.

Can I Paint or Stain New Pressure Treated Timber?

It’s tempting to get the finishing touches done straight away, but it's really best to wait. When you buy pressure treated timber, it’s often still saturated from the treatment process. If you slap a coat of paint or stain on it too soon, you'll just trap that moisture inside, which is a recipe for peeling and a finish that just won't last.

So, how do you know when it’s ready? A good old-fashioned trick is the "sprinkle test." Just flick a few drops of water onto the wood. If the water beads up on the surface, it's still too wet and needs more time. If it soaks in, you're good to go. Just give it a good clean and make sure it's completely dry before you start painting or staining.

You might be wondering about safety, especially for things like garden beds. The good news is that modern pressure treated timber used for home projects is considered perfectly safe for raised vegetable beds. The copper-based preservatives are locked into the wood's structure and are extremely unlikely to leach into your soil in any meaningful way.

If you want that extra bit of reassurance, you can always line the inside of the bed with a plastic membrane. It’s a simple step that creates a solid barrier between the timber and the soil, putting any lingering worries to rest.

Why Has My Timber Turned Grey or Cracked?

Don't panic if you see your timber changing over time—it's completely normal. That silvery-grey look that develops is just the effect of the sun's UV rays. It's only a surface-level change and has zero impact on the timber's strength or its ability to fight off rot.

You might also spot small cracks appearing along the grain. This is known as ‘checking’, and it's just a natural part of the wood drying out and shrinking. These splits are superficial and won't affect the structural integrity of the timber. If you want to keep that original colour and reduce checking, your best bet is to regularly apply a good quality sealant or stain that offers UV protection.

For any project, big or small, getting the right materials is key. From top-quality treated timber to all the fixings and finishes you'll need, you can trust the experts. Burnt Oak Builders Merchants has been supplying trades and homeowners for over a decade. Check out everything we offer over at our online shop.