Welcome to our deep dive into 9mm plywood sheets. If you've spent any time on a building site or in a workshop in the UK, you've definitely come across this material. It hits that perfect sweet spot between being tough enough for the job and light enough to handle easily, making it a firm favourite for builders and DIYers alike.

So, What's the Secret to 9mm Plywood's Versatility?

Think of it like this: you can't tear a single sheet of paper easily if you pull on its edges, but you can rip it from the side. Now, imagine gluing hundreds of sheets together, but with each layer turned 90 degrees to the one below it. Suddenly, you've got a material that's incredibly strong in every direction.

That’s essentially how plywood is made. We take thin layers of wood veneer, or 'plies', and bond them together with a powerful adhesive. The crisscrossing grain pattern is what gives the finished sheet its signature strength and stops it from warping or twisting like a solid piece of timber might.

The 9mm thickness, in particular, is a real all-rounder. It’s got enough substance for serious applications but without the heft and higher price tag of thicker boards. This is why it’s become the go-to for so many projects where you need performance without the fuss.

Why This Thickness Works So Well

The reason 9mm plywood sheets are so popular comes down to a few core benefits that really make them stand out:

- Strength vs. Weight: It offers fantastic structural support for its weight. This means you can lift, carry, and install it without a struggle, but you're not sacrificing durability.

- Budget-Friendly: When you don’t need the brute force of a much thicker panel, 9mm plywood is a far more cost-effective choice, helping you keep project budgets on track.

- Do-It-All Adaptability: Its middle-of-the-road thickness makes it perfect for a huge range of jobs, from structural sheathing and subfloors to building custom cabinets and even decorative wall panelling.

To put it simply, 9mm plywood gives you solid, reliable performance without the bulk. It's the dependable workhorse of the sheet material world, ready for almost any challenge you can throw at it.

This guide is here to walk you through everything you need to know, from the different types and grades you’ll find to practical tips for cutting and finishing. By the end, you'll be able to confidently explore our full range of plywood sheet options and pick the perfect board for your next job.

Understanding Plywood Construction and Types

The real magic behind any plywood sheet, including the versatile 9mm option, is how it's put together. It isn’t just a slab of wood; it's a cleverly engineered panel built for strength and stability. The whole thing is made by layering thin wood veneers, or 'plies', one on top of the other.

The secret sauce is that the grain direction of each layer is rotated by 90 degrees compared to the layer below it. This cross-graining is what gives plywood its incredible resistance to warping, cracking, and splitting – all common headaches with solid timber. Think of it like weaving fabric; that interlocking structure spreads any stress evenly, making the board remarkably strong yet surprisingly light.

Differentiating the Main Plywood Varieties

When you start looking at 9mm plywood sheets, you'll quickly notice they aren't all the same. The type of wood and the glue used to bond the layers are what really define the panel's characteristics and where it should be used. In most UK builders' merchants, you'll generally come across three main categories.

Getting to grips with these differences is the key to picking the right material for your project, making sure you get the performance you need without overspending. Let's break down the most common options.

-

Softwood Plywood: This is the rugged workhorse of the bunch, typically made from woods like pine or spruce. It's strong, fairly lightweight, and budget-friendly. This makes it the go-to choice for general construction jobs like wall sheathing, roofing, and subfloors where you need structural integrity more than a pretty face.

-

Hardwood Plywood: Made from tougher, more durable timbers like birch or oak, this type boasts a much nicer surface finish. Its dense structure makes it perfect for projects where looks are important, such as joinery, custom cabinetry, furniture, and decorative wall panelling.

-

Marine Plywood: This is the top-tier option, built for maximum durability in wet and humid environments. Marine ply is made using fully waterproof glue and high-quality veneers with no gaps or voids, which stops moisture from getting trapped between the layers. It’s absolutely essential for boat building, bathroom fit-outs, or any project that’s going to face the elements.

It's crucial to remember that the name "Marine Plywood" isn't just a marketing term; it refers to a specific manufacturing standard, BS 1088. For genuine marine-grade quality that you can rely on, always look for this certification.

The UK plywood market has its own quirks that can affect what’s available and how much it costs. The industry has seen a shift where a smaller number of major exporters now control a larger slice of the market. This can influence supply chains and has pushed manufacturers to focus on producing more advanced, high-spec plywood grades.

By understanding these core types, you’ll be able to confidently browse our full range of timber sheet materials and pick out the perfect 9mm plywood for your job.

How to Select the Right Grade of 9mm Plywood

Choosing the right 9mm plywood sheet goes beyond just the type of wood. You also need to get to grips with its grade. Think of the grade as a quality score for the plywood's face and back veneers, telling you everything you need to know about its visual appearance and how many natural blemishes to expect.

Getting this right is key to matching the board’s finish to what your project actually needs.

In the UK, we use a straightforward lettering system that runs from A (the best quality) down to D (purely structural). It’s a bit like a school report card for wood. An 'A' grade veneer is practically perfect, whereas a 'D' grade is meant to do a job, not look pretty. Understanding this system is crucial for managing your budget and the final look of your work.

Decoding the Plywood Grading System

You'll often see plywood described with two grades, like 'B/BB'. The first letter tells you about the quality of the "face" veneer (the side you'll most likely see), and the second letter describes the "back" veneer. This clever system allows manufacturers to produce panels that have a high-quality finish on one side while keeping the overall cost down with a lower-grade reverse.

To help you choose the right sheet for your job, we've put together a simple comparison table outlining the most common grades you'll find.

Comparison of Plywood Grades

| Plywood Grade | Veneer Appearance | Common Applications |

|---|---|---|

| Grade A | Smooth, sanded, and uniform. Free of knots or repairs. | High-end furniture, cabinetry, decorative wall panels, joinery. |

| Grade B | Mostly clear with a few small, tight knots. Any repairs are neat wooden plugs. | General joinery, furniture, shelving, projects requiring a good paint finish. |

| Grade C | May have open knots, some splits, and discolouration. Structurally sound. | Sheathing, subflooring, general construction where appearance is not a factor. |

| Grade D | Contains multiple unrepaired knots, splits, and other defects. | Temporary structures, packing crates, hidden structural components. |

As you can see, the grade directly ties to the intended use.

Here's a little more detail on what to expect from each one:

-

Grade A: This is the premium stuff. The veneer is smooth, fully sanded, and looks fantastic. It’s the perfect canvas for staining, lacquering, or painting, making it the go-to for top-quality furniture and visible joinery.

-

Grade B: Still a very high-quality surface, Grade B allows for a few minor, natural characteristics, like small, tight knots. Any larger imperfections will have been expertly patched with neat wooden plugs. It’s a brilliant all-rounder for most visible jobs where a flawless, uniform finish isn't the top priority.

-

Grade C: With this grade, function starts to take over from form. C-grade veneers can have open knots, splits, and some colour variations. While you wouldn't use it for decorative work, it provides solid structural performance for things like wall sheathing or subflooring.

-

Grade D: As the lowest grade, this veneer is all about structural integrity and nothing more. It can have plenty of knots, splits, and unrepaired defects. You’ll find it used for temporary shuttering, packing cases, or any job where the plywood will be completely hidden from sight.

The key takeaway is simple: only pay for the finish you actually need. There’s no point splashing out on an A-grade sheet for a subfloor, just as you wouldn't use a D-grade panel for a beautiful cabinet door.

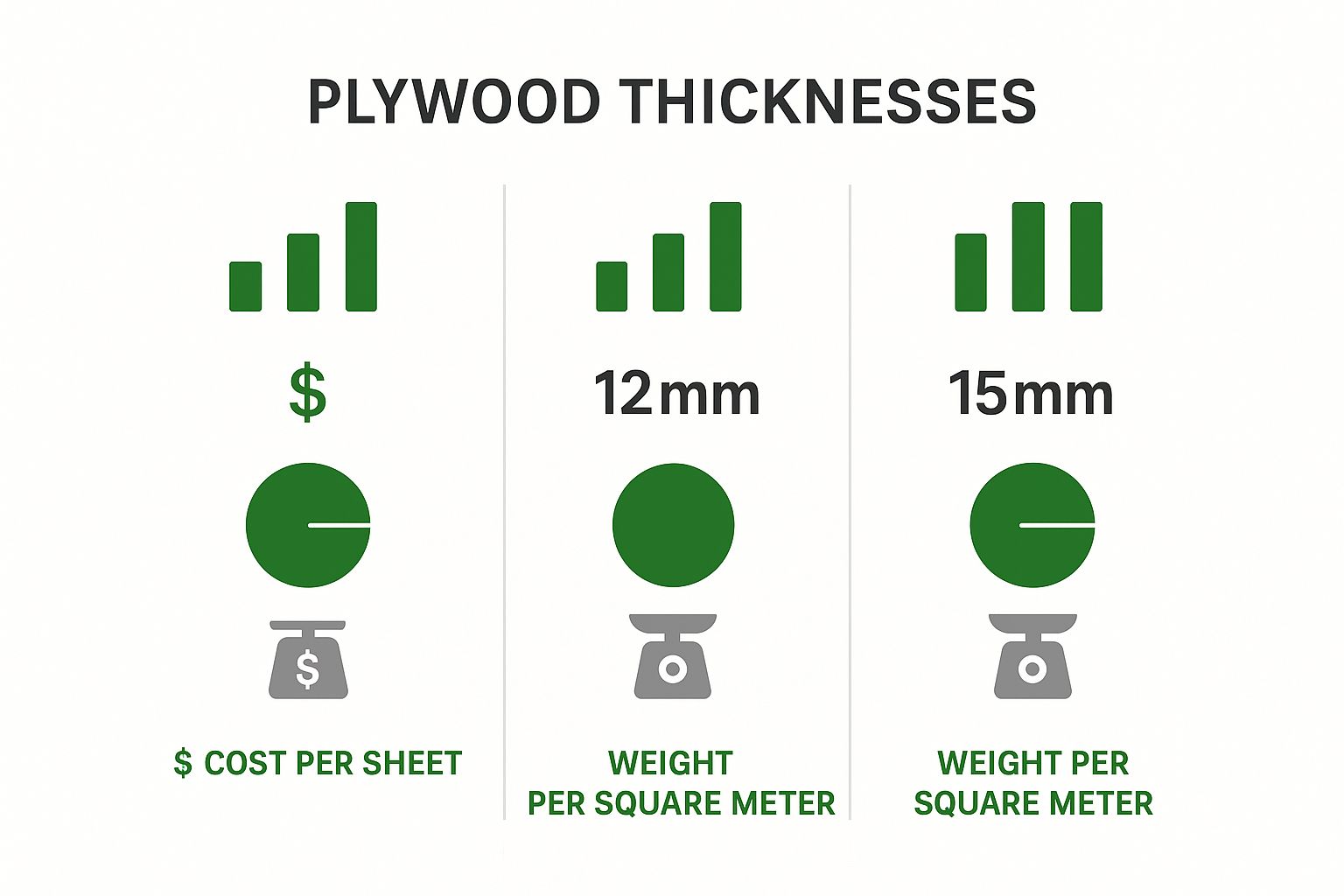

This image gives you a quick visual comparison of how different plywood thicknesses, including our versatile 9mm option, stack up against each other in terms of cost and weight.

As you can see, 9mm plywood sheets really hit a sweet spot. They offer a significant weight advantage over the thicker, heavier panels while keeping costs manageable, which is exactly why they’re so popular for a huge range of applications.

Where You’ll Find 9mm Plywood Sheets in Action

You really get a sense of just how useful 9mm plywood sheets are when you see the sheer variety of jobs they're used for. This one thickness has become a go-to material for builders, joiners, and DIYers alike, and for good reason. It hits that sweet spot of being strong but not too heavy, and affordable enough for both big structural jobs and smaller, more detailed projects.

On a building site, its strength-to-weight ratio is its biggest asset. You’ll often see 9mm plywood used as wall sheathing, where it acts as a rigid skin that stops timber frames from twisting or swaying. It’s also a popular choice for the roof deck on sheds, summerhouses, and other outbuildings. It provides a solid, flat surface for roofing felt or shingles without dumping a huge amount of weight onto the rafters.

In the Workshop: Joinery and Furniture

Step away from the construction site and into the workshop, and you'll find 9mm plywood is just as popular with joiners and cabinet makers. Its stability and smooth face make it an ideal stand-in for solid wood, especially in places where timber might warp or be too bulky.

You'll find it used for things like:

- Cabinet Backs: It’s perfect for adding rigidity and pulling a cabinet carcass perfectly square.

- Drawer Bottoms: It provides a strong, slim base that doesn't steal precious storage space.

- Custom Furniture: From internal shelves and workshop jigs to visible panels in sleek, modern designs.

From Home Projects to Commercial Fit-Outs

For anyone tackling a project at home, 9mm plywood sheets are a dream to work with. You can knock together custom shelving, build a solid workbench, or even make planters for the garden using just a few basic tools. The possibilities really are endless.

This same versatility makes it a valuable material in the commercial world, too. Plywood is a key player in the UK’s interior design and construction sectors—a market valued at around £1.3 billion. As retail and commercial spaces expand, they need materials that are both dependable and flexible. Think about the rise of pop-up shops and temporary installations; 9mm plywood is ideal for building quick, sturdy displays and partitions that can be put up and taken down easily. If you want to dig into the numbers, you can explore UK plywood market insights on imarcgroup.com.

Plywood's adaptability makes it a cornerstone material. Whether it's providing structural support behind the scenes or taking centre stage in a custom furniture piece, its performance is consistent and reliable.

From the hidden parts of a building's frame to beautifully finished furniture, 9mm plywood proves its worth over and over. It's this incredible range that keeps it one of the most popular and widely used sheet materials on the market.

Getting the Best Results: Handling, Cutting, and Finishing Your Plywood

Working with 9mm plywood sheets is straightforward, but a few pro tips can make the difference between an average job and a truly professional finish. Getting it right starts from the moment the sheets arrive.

First things first, never lean your plywood against a wall. It might seem harmless, but even a short time in that position can cause it to bow or warp. The best way to store them is flat on a level surface, ideally on evenly spaced bearers (just scrap pieces of timber will do) to let air circulate underneath. This keeps them perfectly straight and ready for your project.

How to Get a Clean, Splinter-Free Cut

One of the biggest frustrations when cutting plywood is 'tear-out'—that annoying splintering you get along the cut line, especially on the top veneer. It can mess up a perfectly good piece, but thankfully, it’s easy to prevent once you know the tricks of the trade. The key is to support the wood fibres right where the blade meets the surface.

Here are a few simple methods that work every time:

- Use a Fine-Toothed Blade: The more teeth on your saw blade, the cleaner the cut. It takes smaller bites out of the wood, which dramatically reduces the chance of chipping that delicate face veneer.

- Score Your Cut Line: Before you fire up the saw, take a sharp utility knife and a straight edge and firmly score the line you're about to cut. This slices through the top wood fibres cleanly, creating a perfect channel for your saw to follow.

- The Masking Tape Trick: A classic for a reason. Stick a strip of good-quality masking tape along the cut line and press it down firmly. The tape holds the surface fibres together, preventing them from lifting and splintering as the blade passes through.

"A sharp blade and a steady hand are a good start, but supporting the wood fibres is the real secret to a splinter-free cut. Taking that extra minute to score the line or apply tape will save you hours of sanding and frustration later."

Finishing Touches for a Lasting, Great Look

Once everything is cut and assembled, the right finish not only protects your 9mm plywood but also brings out its best features. The path you take really depends on the look you're going for. Of course, having the right gear helps, and a good grasp of the essential tools for homeowners is always a solid foundation for any finishing job.

Sanding is non-negotiable. Begin with a medium-grit sandpaper, something around 120-grit, to level out any minor imperfections. Then, switch to a finer 220-grit to get that silky-smooth surface that’s ready for a topcoat.

If you plan to paint, don't skip the primer. Plywood is quite thirsty, and a quality wood primer seals the surface. This stops the paint from soaking in unevenly and gives you a much more durable, even, and professional-looking result. For those who love the natural wood look, a good stain can really make the grain pop. Just be sure to follow it up with a couple of coats of clear varnish or lacquer to shield it from moisture and everyday wear and tear.

Choosing Your Supplier in the UK Market

You've done the hard work of figuring out exactly which type and grade of 9mm plywood sheet you need. But there's one last crucial step: finding the right place to buy it from. Sourcing your materials isn't just a transaction; choosing a reputable supplier is as vital as picking the right sheet, because it affects everything from the quality of your finish to the smoothness of your entire project.

A good builders' merchant is more than just a shop. They’re a partner. You want a place with a wide range of stock on the ground, so you're not forced to compromise on the structural, hardwood, or marine ply you've set your mind on. It's also about the people. Talking to knowledgeable staff who've seen it all can make a huge difference. They can confirm if your chosen grade is the right call for the job, a bit of advice that can genuinely save you time and headaches down the road.

Why a Trusted Merchant Matters

So, what do you really get from a reliable supplier? It boils down to a few key things that protect your investment and your project's integrity.

- Guaranteed Quality: You can be confident the plywood meets all UK standards and is graded correctly. No nasty surprises.

- Sustainable Sourcing: A good merchant cares where their timber comes from. Look for certifications like FSC or PEFC, which means it’s from responsibly managed forests.

- Expert Advice: Got a technical question? The team on hand should be able to give you a straight, practical answer.

One of the biggest advantages is being able to see the product for yourself before you commit. This is especially important for decorative work where the look of the veneer is everything. And of course, delivery matters. You need a supplier you can count on to get your materials to site on time and in perfect condition. For a breakdown of how we handle this, you can check our straightforward delivery information.

In a market where timing is everything, a reliable supply chain is non-negotiable. A great merchant provides a steady flow of high-quality materials, ensuring your project stays on track without delays or last-minute substitutions.

The UK plywood market is on an upward trend, projected to grow at a +2.5% CAGR between 2024 and 2035. This points to a growing demand for better-quality products, making your choice of supplier more important than ever. By partnering with a trusted name like Burnt Oak Builders Merchants, you’re not just buying plywood; you’re investing in premium materials backed by expert service.

Your 9mm Plywood Questions Answered

When you're in the thick of planning a project, a few questions about materials are bound to pop up. We get it. To help you get the answers you need without the fuss, we've pulled together some of the most common queries we hear about 9mm plywood sheets from builders and DIYers alike.

Think of this as a quick, no-nonsense guide to help you make the right choices and get the best results from your materials.

Is 9mm Plywood Strong Enough for Flooring?

While it’s a tough and versatile board, 9mm plywood is a bit too thin to be used as the main structural subfloor. For that job, UK building standards usually point towards chunkier 18mm or 22mm boards to handle the load and span across floor joists without any give.

Where 9mm really shines, though, is as an overlay. If you've got an existing subfloor like old floorboards or chipboard, laying a 6mm or 9mm sheet on top gives you a perfectly flat, stable base. It’s the ideal trick for getting a flawless finish when you’re putting down vinyl, LVT, or carpet.

Pro Tip: Using 9mm plywood as an underlay is the secret to a professional-looking floor. It smooths out any bumps and imperfections from the subfloor below, stopping them from telegraphing through to your new flooring. Just make sure it’s screwed down tight!

Can I Use 9mm Plywood Outside?

This one comes down to choosing the right tool for the job. Your standard interior plywood, whether it's softwood or hardwood, simply won't survive outdoors. The glue holding the layers together isn't waterproof, and it will quickly delaminate and fall apart once the rain gets to it.

For any project that will be exposed to the elements, you need to reach for Marine Plywood. It’s made with a completely waterproof adhesive (often called WBP, or Water Boil Proof glue) and uses top-quality veneers with no gaps inside. This construction is what makes it the only reliable choice for everything from garden planters and shed repairs to boat building.

How Much Weight Can a 9mm Plywood Sheet Hold?

There's no single answer here, as the load a 9mm sheet can handle really depends on a few things: the type of wood (hardwood is typically stronger), how far apart its supports are, and how the weight is spread across the surface.

As a rule of thumb, it’s perfect for lighter-duty shelving for things like books, tools, or workshop supplies. If you're planning to store something heavier, the key is to shorten the distance between the brackets. You could also add a timber batten along the front or back edge to give it extra backbone and stop it from bowing over time.

Ready to find the right 9mm plywood sheets for your job? At Burnt Oak Builders Merchants, we keep a great range of high-quality plywood in stock, ready for any application. Take a look at what we've got and let us get the materials you need delivered straight to your door or site. Visit us online today to get your order started.